This is a summary report on ISMChina’s research project on digital transformation of supply management in China.

Volunteers who participate in ISMChina’s digital transformation research project and those who follow our project will remember ISMChina’s digital transformation project starting in 2020. We have had a series of surveys, reports and interviews to share.

The purpose of this project is to understand the current situation of China’s digital transformation in supply management, and what successful practices are worth learning from. It is also hoped to build a platform for exchange and learning to help members understand the knowledge and application of digital transformation in supply management.

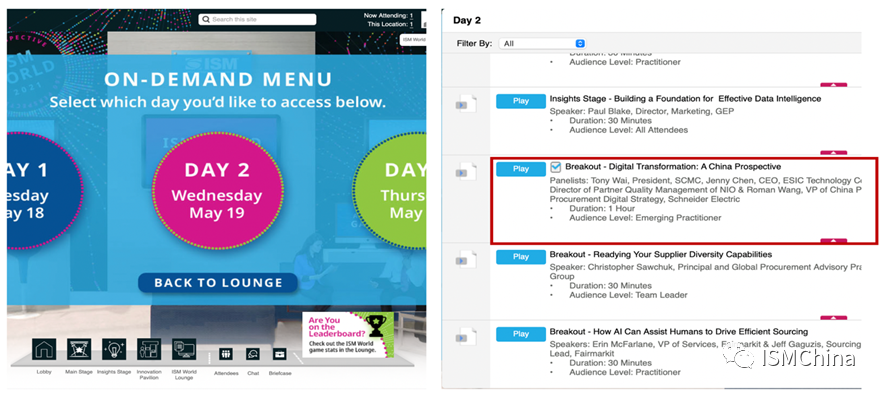

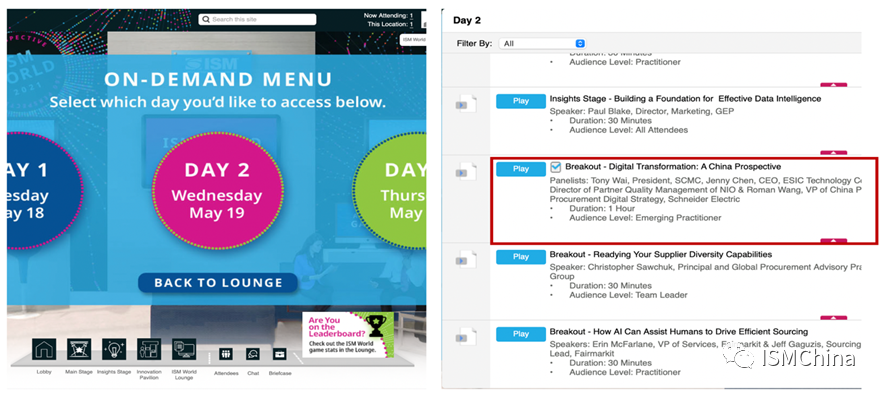

Our project includes a survey of digital transformation and interviews with more than 20 companies. Finally, at the suggestion of Tony Wai, Chairman of ISMChina, we submitted the project to the ISM World Global Summit, and our project was not only selected, but also broadcast in two sessions, which is very rare according to the organizer. I think this means not only a greater awareness of the application of digital transformation in supply management and a deeper understanding of the current situation and best practices in China, but also a meaningful output of our project, thanks to the participation and contribution of the project team over the past year.

Starting from this issue, I would like to share our speech at the 2021 ISM World Summit for you in three parts, and also mark the end of our project and start the next journey. Please pay attention to ISMChina’s follow-up exchange and knowledge sharing platform on digital transformation.

Chairman Tony Wai, ISMCHIN said:

This ISMChina digital transformation research project is based on the “digital transformation” research in the core of the global supply chain in China, covering local and multinational enterprises, and is a representative digital development benchmark. The project team decided to display our research results on the world’s highest standard procurement professional platform.

The annual international summit “ISM World” organized by the 100-year purchasing professional leadership organization ISM (Institute for Supply Management) brings together more than 3,000 purchasing professionals from around the world to participate. Being selected to present research at this international conference means worldwide sharing and attention, and it also requires a high level of presentation.

Due to the global epidemic situation, this year’s conference was held online, which made it easier for more people from all over the world to participate in the conference. At the same time, the successful recording and warm response of the conference allowed our participants to gain a good experience and sense of achievement in terms of technical operation and screen performance. In this short series, Jenny will walk you through our entire project experience, and together we will put together some discoveries and insights. After that, we will bring you a live report from the ISM World Conference.

The 2021 ISM World Global Summit is something special

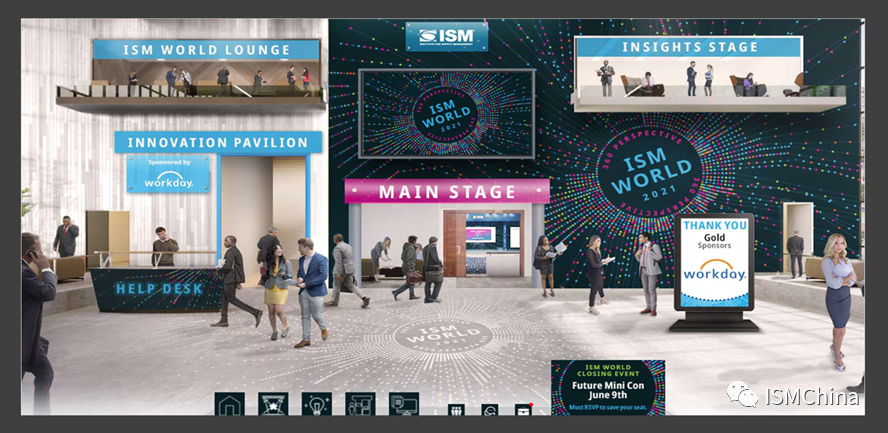

This year, the ISM World under the epidemic is very unusual. Take a closer look at the virtual main venue of the entire summit, and you’ll see that the ISM organization has taken great care to recreate the offline experience as truly as possible.

This is usually a high quality content rich sharing, not because it is online sharing is weak. The entire summit lasted for three days, and each day there were wonderful shares from companies and organizations from various countries. We hope to sort out these shares for our members in the future. Let’s take a look at the project that ISMChina submitted.

Speech Abstract:

Exploring uncharted Territory – ISMChina Digital Transformation Research – a Chinese perspective

Digital technology is disrupting our society at an alarming rate. We want to know how digitization will affect the manufacturing supply chain and what we can do about it. ISMChina Council Tony Wai, Leonard Fok, Lou Zhou initiated the digital research project, appointed Jenny Chen to lead the project, and accepted voluntary applications from members, from which we selected 12 members with supply chain expertise from the manufacturing industry. The team we have assembled has three main tasks: to understand the current situation of digital transformation of the manufacturing supply chain in China, best practices of digital transformation, and to build a platform for learning and exchange at a later stage.

The project lasted eight months, collected 200 questionnaires, and interviewed managers or supply chain experts from nearly 20 enterprises, which were hand-selected by the project team as practitioners and leaders in digital transformation in various industries. Our selected industries are electrical, automotive, medical devices, home appliances and aerospace. Our projects gather a wealth of first-hand information, enrich our knowledge and ultimately generate insights to explore a clearer path for the digital transformation of supply chains.

Audience Takeaways:

Most companies in China are eager to learn more about digital transformation and are willing to participate. We were fortunate to get the companies to open their companies and share their testimonies and opinions without reservation, which allowed our project members to gain a multi-faceted perspective, which came together and ultimately formed our insights. We believe these insights may be beneficial not only for manufacturing in China, but also for manufacturing globally.

In this share, we will build around these insights:

- The most fundamental and deepest driving force for enterprise digital transformation should come from better serving customers, that is, creating greater value for customers. At present, most enterprises take “cost reduction and efficiency increase” as the driving force of digitalization, which should only be an inevitable result of digitalization.

- Should successful digital transformation be driven from the top down or from the bottom up? Or is it the perfect combination of Top-Down strategy development and persistence across the organization, coupled with Bottom-Up executive feedback?

- Digital transformation is actually a deep-seated change that requires enterprises to embrace digital change with an open mind. It may mean not only adjusting organizational structure and culture accordingly, making changes in talent acquisition and development, consciously cultivating the culture of a digital company, but also revisiting or even abandoning proud experiences of the past.

- One obstacle to digital transformation is user resistance. How do you turn “users” from contributors to data to beneficiaries of data? Is it only the combination of the two that can truly solve the problem of creating and sharing data and creating value?

- Those familiar new technologies such as big data, artificial intelligence, material network, blockchain… How relevant is the digitization of manufacturing supply chains? What impact and effective help will it bring?

Speeches and guest introductions

The whole sharing has two parts. The first part, co-hosted by Tony Wai and Jenny Chen, shared the background of the project, and the second part was an interview. We were fortunate to have Roman Wang, Vice President of Procurement at Schneider Electric, and Frank Ma, Senior Quality Director at NIO, to participate in the interview, which gave us the opportunity to hear their share and learn more about the successful application of digital in the enterprise.

Tony Wai

Tony is the President of SCMC, which provides professional skills and digital transformation training and consulting services to leading global companies and is a pioneer in bringing the CPSM certificate program to the Chinese market. Tony is the founder and President of ISMChina, a division of ISM.

Jenny Chen 陈容

Jenny is currently the founder and CEO of Feng Zhi Technology Co., LTD. Fengzhi Technology is committed to helping enterprises achieve effective procurement management, and is also a provider of digital procurement software system and supplier collaboration platform SRM, serving many large and medium-sized enterprises in China. Jenny has 20 years of experience in the procurement field, guiding the planning and implementation of the procurement strategy of the enterprise, coaching the professional skills and strategic process concept of the procurement manager, and is the chief designer of the SRM digital procurement management software system. Jenny is also the Chair of the ISMChina Digital Transformation Committee and an ISMChina Board Member. Jenny has previously worked for Solectron, Nokia, Baxter.

Panel Speakers:

Roman Wang

Roman is currently Vice President of Schneider Electric, responsible for Schneider Electric’s China Sourcing and global sourcing digitalization strategy. Roman is an experienced procurement professional who has successfully driven change in corporate procurement organizations in the electrical and mechanical industries where she has served. Today he is leading Schneider Electric’s purchasing department towards agility and digitalization. He has been working in supplier management for 20 years and has extensive theoretical and practical experience in supplier quality, category management, project sourcing, procurement and supply chain management. Prior to Schneider, Roman worked for companies including Emerson, Pentair Water, BB Electronics and Rexnord.

Frank MA

Frank is the Senior Director of Supply Chain Quality at NIO and an expert in supply chain management in the automotive industry. Frank has extensive experience in supply chain quality management and development, lean manufacturing and problem solving. Frank has worked for Delphi, FCA China and Qoros. Frank joined NIO in 2015.

Well, that’s all for this sharing, and we look forward to introducing the content we share in ISM World in the next few issues.