This is the second article shared by ISMChina in China’s Supply Management Digital Transformation research project and ISM World Global Summit. In the previous article, we shared the main thrust of the project, summary and introduction of the speakers. In this article, we will get closer to our sharing at the summit to learn more about what we shared.

Our one-hour presentation at the summit was delivered by four guests, Tony, Jenny, Roman and Frank. After Tony’s concise and concise opening, we went straight to the two topics we shared, and I am happy to go over them again for the friends who follow our project, ISMChina members and the friends of ESiC public account.

Digital Transformation, A China Prospective

《数字化转型中国企业ISMChina调查报告》(ISMChina Survey of Chinese Enterprises in Digital Transformation)

The first part of the presentation is based on a questionnaire about digital transformation in Chinese enterprises. We have done a detailed introduction of this survey on the public account in May 2020, and interested partners can review the content of the entire survey report through the link.

Digitization is no longer a new topic, digitization has profoundly changed all aspects of our lives, bringing us great convenience, but also subvert the traditional way of life and infrastructure. From our daily routines, to travel, to socializing, our society is constantly adapting and innovating for the digital age.

Compared to the digitization in our lives, the traditional manufacturing industry seems to still be on the sidelines. Is digitization changing supply chain management in our manufacturing industry? Do manufacturing leaders need to pay more attention to digitalization?

Our survey is based on the manufacturing industry in the land of China. These manufacturing industries include multinational companies and local enterprises. Let’s take a look at what the survey has brought to us.

1. What drives digitalization in the enterprise?

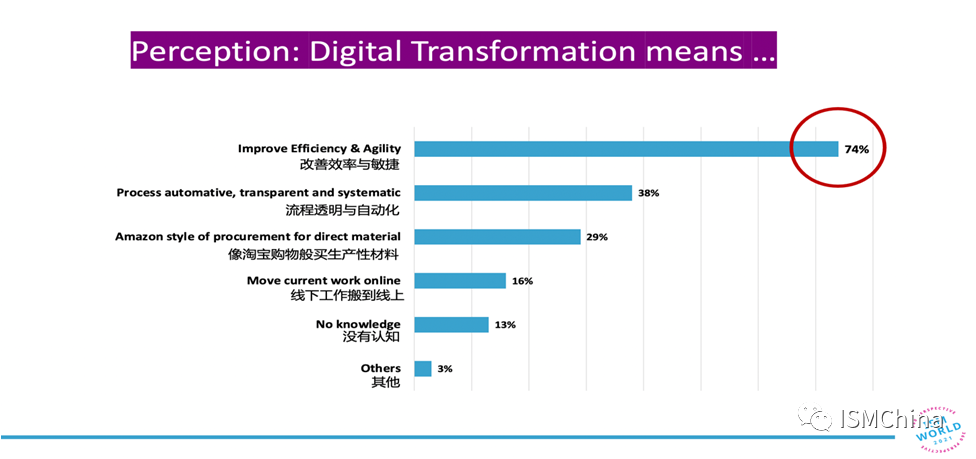

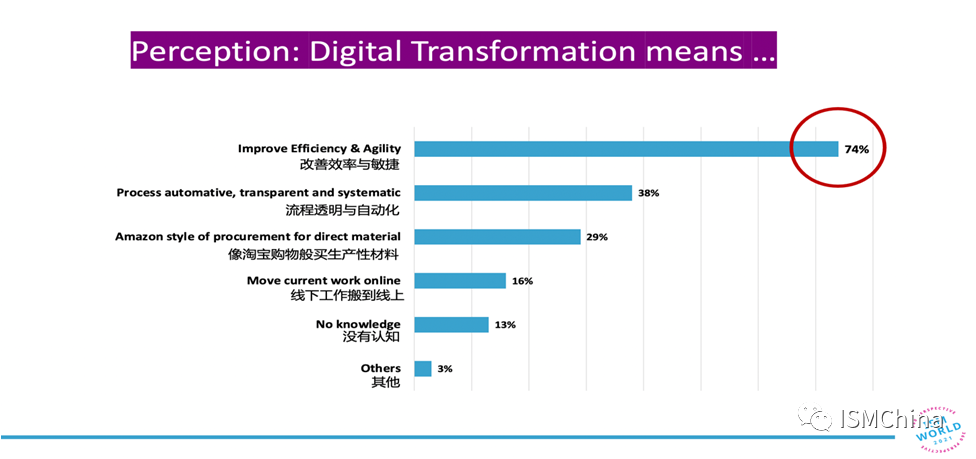

In our survey, we gave five reasons to drive digital transformation, and 74 percent of respondents chose increasing efficiency and agility, followed closely by automating and making processes transparent.

The five reasons given are: 1) improving efficiency and agility 2) process automation and transparency 3) Buying productive materials like you buy on Taobao 4) moving offline work to online, 5) other)

In fact, in the subsequent interview with the company, we gained a very important perspective and were deeply impressed. At the time of the questionnaire, we may not have this understanding, so this option was not included. As this perception became clear, our project team agreed that this was indeed an important motivation for digital transformation. However, from the fact that only 3% of respondents chose “Other”, the other options we gave at the time are still in line with the current mainstream cognition.

Efficiency and agility, which most surveyors agree on, may be just one result of digitalization. So what is this motivation? You will learn our answer in the third part of this sharing, which is also a very important insight for us. Agree or disagree, you can reply to us.

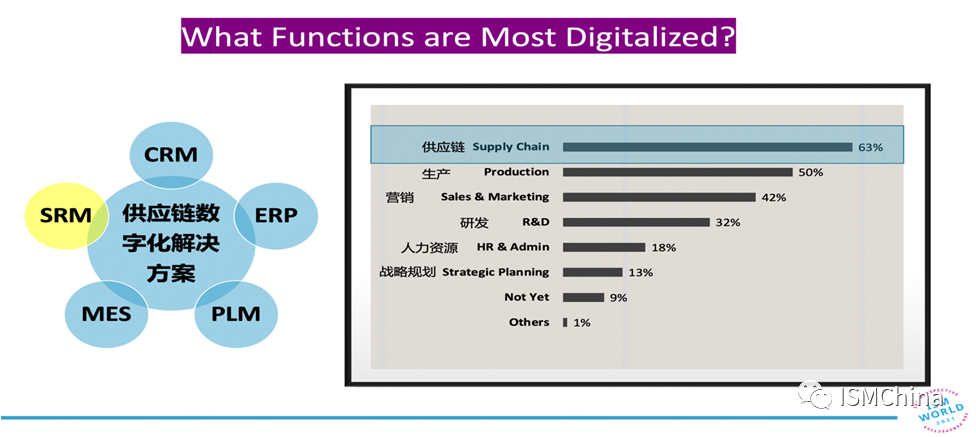

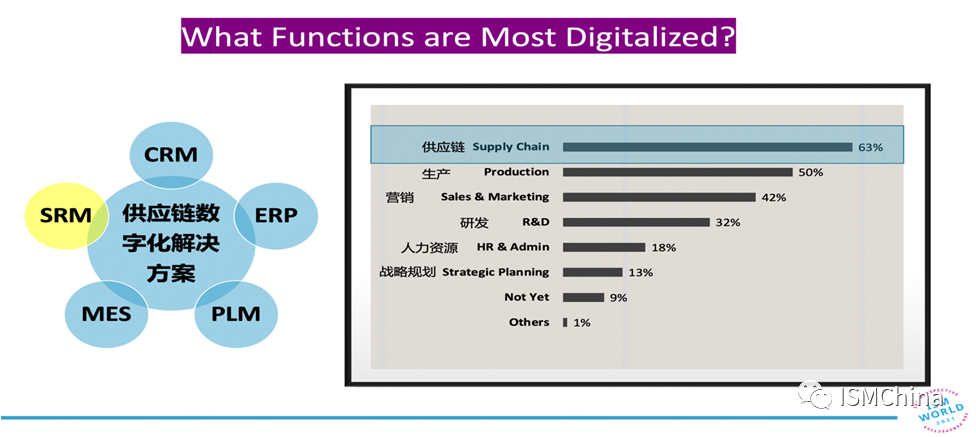

2. In which functions has the company been digitized the most?

For traditional manufacturing have these functions, management and strategy, marketing, human resources, production, research and development and supply chain, the most hot is the supply chain.

Why supply chain? That’s the way I look at it. In the field of supply chain, there are several mainstream digital solutions, and the emergence of these digital solutions, I think, is accompanied by the development of manufacturing industry in China in the past 20 to 30 years.

In the 1990s, when China opened its door to the outside world, a large number of foreign enterprises poured into China, gaining the advantage of low cost of China’s labor infrastructure and vast potential market, but also brought the vigorous development of China’s supporting manufacturing industry. One of the key purchasing metrics I had at Nokia back then was the localization of material purchases. At that time, the supporting enterprises, as long as they can produce, they can make money. ERP software, the end-to-end software used to balance the supply of demand and production, was first developed and is still in great demand today.

However, when more and more supporting enterprises flood the market, the problem is no longer whether it can be produced, but whether it can be produced efficiently and cost-effectively, improving the output of machines and humans, reducing waste, and balancing the capacity of machines becomes more and more important. MES software, which is used to manage the production capacity of various machines and equipment and the balance of materials and production of various processes, began to enter the market and gradually became needed;

When China’s local supporting enterprises and fountifiers gradually gain more production and market experience, they are no longer satisfied with only parts suppliers, but ambitious to rise to the upstream of the supply chain to become product manufacturers. They need to understand the needs of the market, design, produce, release and iteratively manage the products. PLM (Product Life Management) product life cycle management software came into being.

SRM – vendor relationship software, is only in recent years, and the demand is growing in the past two years. Personally, I think the name doesn’t convey all the functions of the system. Perhaps the name is a reference to the earlier and very popular CRM customer relationship software. As a business designer and architect of SRM systems, I have witnessed the rapid growth of the SRM market in recent years. SRM is the result of more refined procurement management. It interconnects with a number of systems, inputting master data of suppliers and material prices for ERP, coordinating supplier confirmation, delivery and payment for ERP orders, and telling us the advantages of supply and areas to be improved by a large number of order transaction data, so as to achieve a closed loop of procurement management.

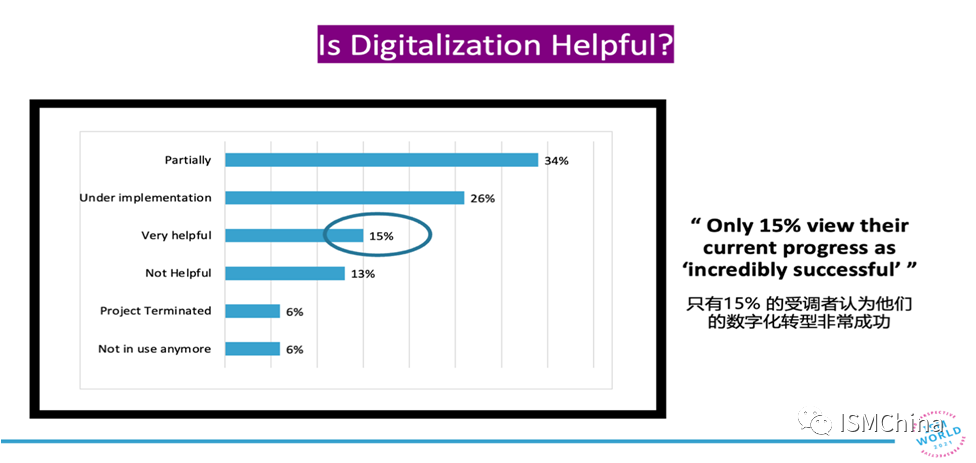

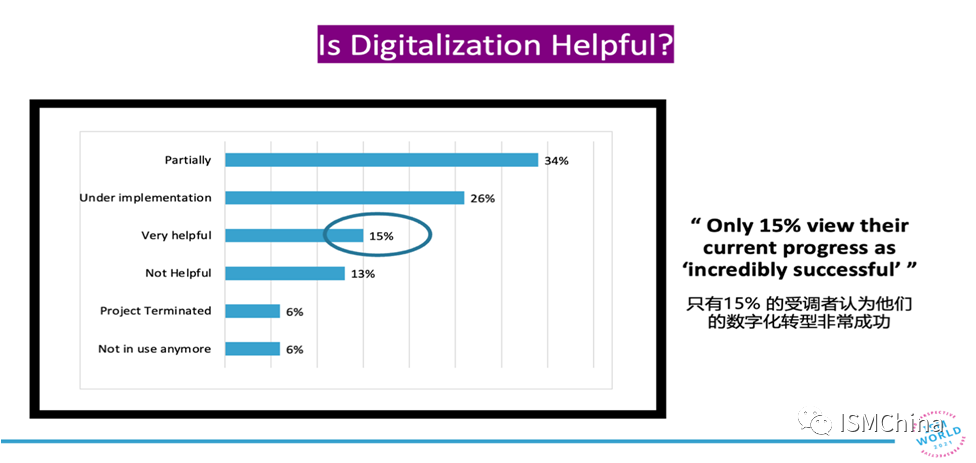

3. Has digitalization helped?

Digital is so popular that leaders of companies that have not yet digitized are also thinking and acting, but truly digital successful companies are still rare. Only 15 percent of respondents consider digital to be very successful. Half of this 15% comes from foreign-funded enterprises.

It seems that, despite the boom and boom of digitalization, for manufacturing, it is still a stage of infancy and growth, and its benefits have not yet been truly reflected. Businesses are all on the same starting line, and if you believe that digital will bring value, now is the time, and the watershed will emerge over the next few years.

If we look at the investment of enterprises in digital, only half of the respondents know the investment of companies in digital, 42% of enterprises, mainly small and medium-sized enterprises invested less than 1 million yuan, and the investment of more than 10 million yuan, most of the companies from the international or large manufacturing industry.

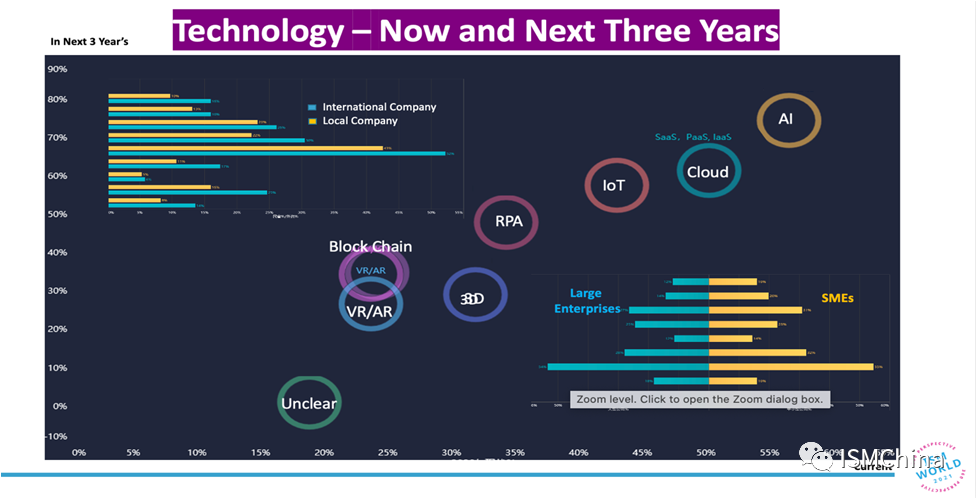

4. What are the digital technologies now and in the next three years?

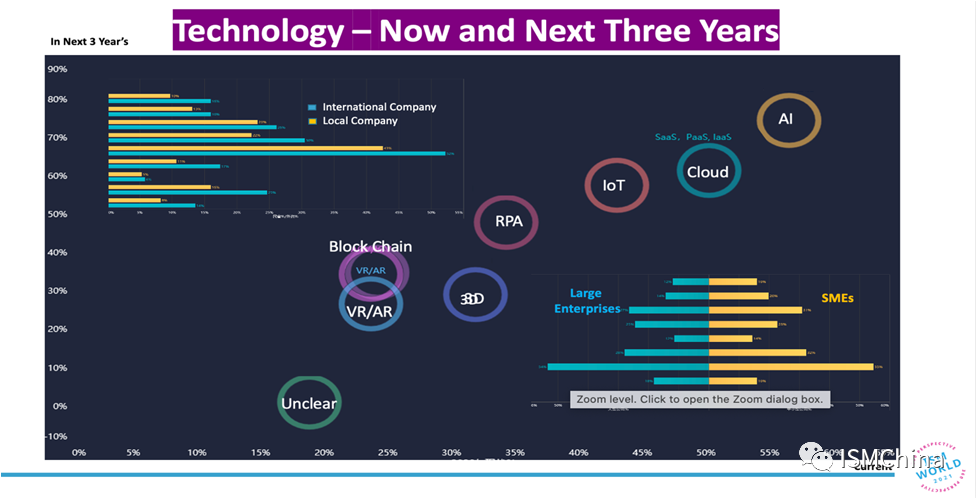

Why is digitalization mentioned in recent years and growing more and more rapidly? In the past few decades, the processing power of chips, the bandwidth of communications, and the amount of data stored have reached exponential growth, laying the technical foundation for the vigorous development of digitalization;

AI- Among these technologies, there are well-known AI technologies, which are not surprisingly given the highest attention by respondents. This may be because AI technology has been successfully and widely used in image recognition and speech recognition, so people have high expectations for AI technology to be used in other areas of application, such as supply chain.

The Block Chain. Blockchain technology, the concept of decentralization, seems to be a perfect solution for supply chains. However, both foreign and domestic surveys show that the application of blockchain in digital is far from expectations.

Cloud technology is the basic technology of digitalization, among which PaaS, IaaS, SaaS have been widely used, and will certainly have more development and application in the next few years;

Other technologies, such as 3D printing, are limited by high production costs and are only used in a limited number of areas;

Thanks to the cloud technology, the rapid development of communication technology and induction technology has greatly improved the speed and efficiency of data collection and transmission, and significantly reduced the cost. The application of IoT technology has gained great development in recent years.

Among the companies we interviewed, RPA was a technology cited by respondents with high frequency. It brings real benefits to the enterprise in process automation, greatly reducing duplication of work. Save the operator a lot of time to do more valuable work. That sounds exciting.

For technology, our feeling is that it is definitely not the bottleneck of digitalization, whether digitalization is successfully applied is not about whether there is advanced and mature technology, but more about the understanding and combing of business needs. When it comes to technology, all companies have an equal opportunity to disrupt existing business models and explore the enormous benefits of digitalization.

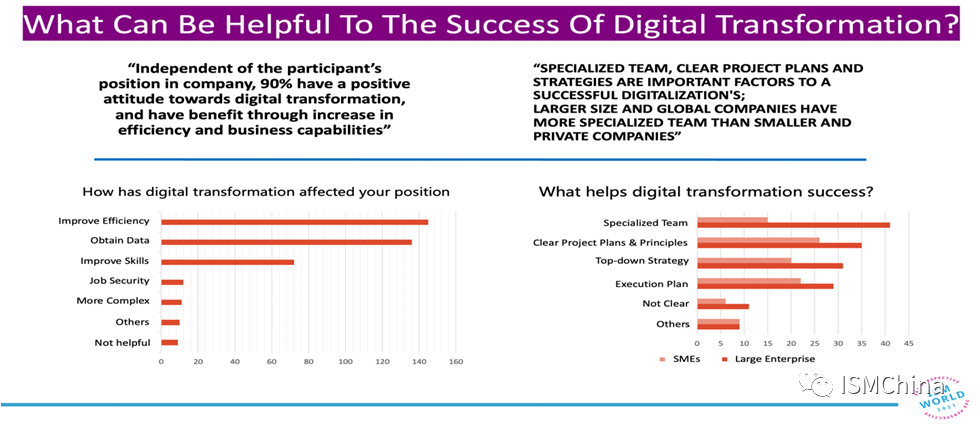

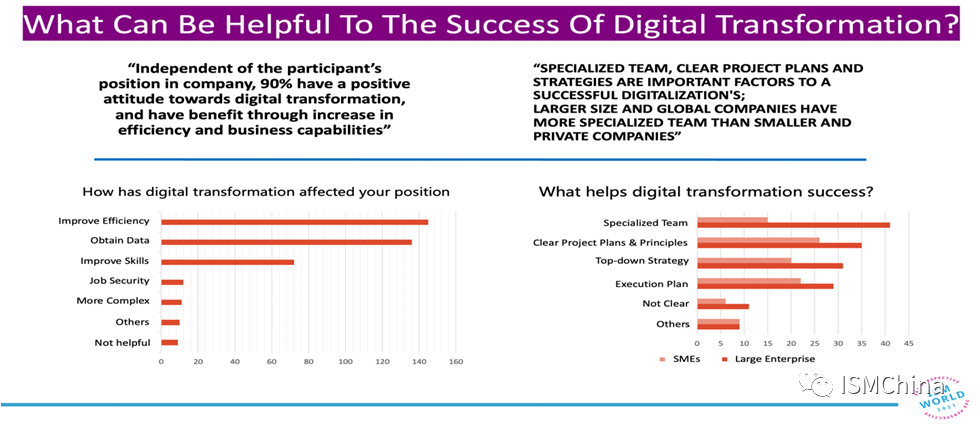

5. What are the elements of digital success?

Technology is not an obstacle, and there is no doubt that digitalization will bring success to enterprises, but not many companies have successfully applied digitalization. What are the barriers to digital success?

According to our survey and interviews, no matter the size of the company, whether it is international or local, digital talent and knowledge are the most scarce. We learned from the companies we interviewed that their HR managers are joining the digital talent war and are willing to pay a lot of money to hire digital talent.

What are the factors that lead to digital success?

- Digital professional team

- Clear goals and project plans

- Execution strategy from the top down

In the following live interview, we will focus on the elements of digital success, so it is worth looking forward to. We will take you close to two successful digital companies: multinational enterprise – Schneider, where Roman Wang, Vice President of Schneider Electric, brings us a wonderful story of Schneider’s digital transformation; Another local new energy local car company was born a digital enterprise – NIO Automobile, Frank Ma, senior director of supply chain quality, brought us a wonderful story of NIO’s digital practice.

Stay tuned!